Why should you choose Rotair air compressor?

With technological progress, more and more importance is attached to efficiency, reliability and cost-effectiveness in the purchase of equipment. Especially in the construction industry, where compressed air plays a key role, choosing the right air compressor is extremely important and it needs to be cost efficient.

One of the leading manufacturers on the Western market is Rotair, which has been consistently co-creating and improving the entire compressed air industry for over 60 years. On this page you will find many reasons why Rotair solutions may be the best investment for your business.

Combustion engines from world-renowned manufacturers

One of the most important factors when choosing a compressor is its efficiency. Mobile air compressors are driven by an internal combustion (or electric) engine through a belt or direct drive.

Rotair compressors are known for their components derived only from well-known, reputable solutions on the machine market. Engines of well-known manufacturers such as: Honda, Kubota, Kohler, Yanmar, Cummins, Perkins, JCB have been permanently present in Rotair combustion powered air compressors for decades.

❗Appropriate power of the combustion engine makes the efficiency of the compressor and the reliability of its declarations translate into lower operating costs and purchase costs of the combustion compressor itself.

Combustion engines are properly matched to the capacity that our customers need, therefore the ideal ratio of kW to capacity.

For every 1 kW of engine power, there is:

- 142 l/min air flow at 7 bar

- 134 l/min air flow at 10 bar

- 101 l/min air flow at 12 bar

- 82 l/min air flow at 14 bar

Competitive differences

Many reputable solutions use a similar range of engines that can be found in Rotair mobile air compressors.

One thing worth noting is the so-called “Downsizing” of screw compressor parameters by competitive solutions, due to the lack of appropriate internal combustion engines that meet exhaust gas emission standards.

❗Therefore, most manufacturers of mobile air compressors use engines from a higher range of their products, e.g. for a capacity of 3.5 m3 at a pressure of 7 bar, they use the same engine as for a compressor with a capacity of 5 m3 at 7 bar – which directly translates into higher purchase costs, operation and servicing.

Reliability and durability of the screw compressor

Equipment reliability is the key to completing any project. Rotair air compressors are known for their robust construction and high-quality components, from the combustion engine to the entire screw compressor system, which ensure reliability and long-term operation.

Thanks to careful manufacturing and the Kaizen philosophy, Rotair air compressors are able to withstand the toughest operating conditions, giving your company the confidence that our solution performs its task with maximum efficiency and precision.

Competitive differences

✅The entire screw compressor is significantly different from competing solutions. The block and set of bolts have been manufactured, designed and patented by Rotair, with a guarantee of 10,000 hours of work for the seals of the screw block. The life of the Rotair screw set is estimated with minimum of 15.000 working hours on construction site.

✅The installed bolt sets are direct drive; they do not have a mechanism that multiplies the revolutions of the gear wheel. This type of solution reduces the possibility of wear and tear of the set of bolts and its overheating, guarantees noise reduction and lower fuel consumption.

✅The design of the screws patented by Rotair is low-failure due to its simplicity. The incomparably larger, slow-running screw ensures a complete lack of vibrations damaging the fastening and sealing elements – thanks to this, Rotair ensures the lowest level of noise coming from the screw compressor, without the need for amortization.

Operating costs

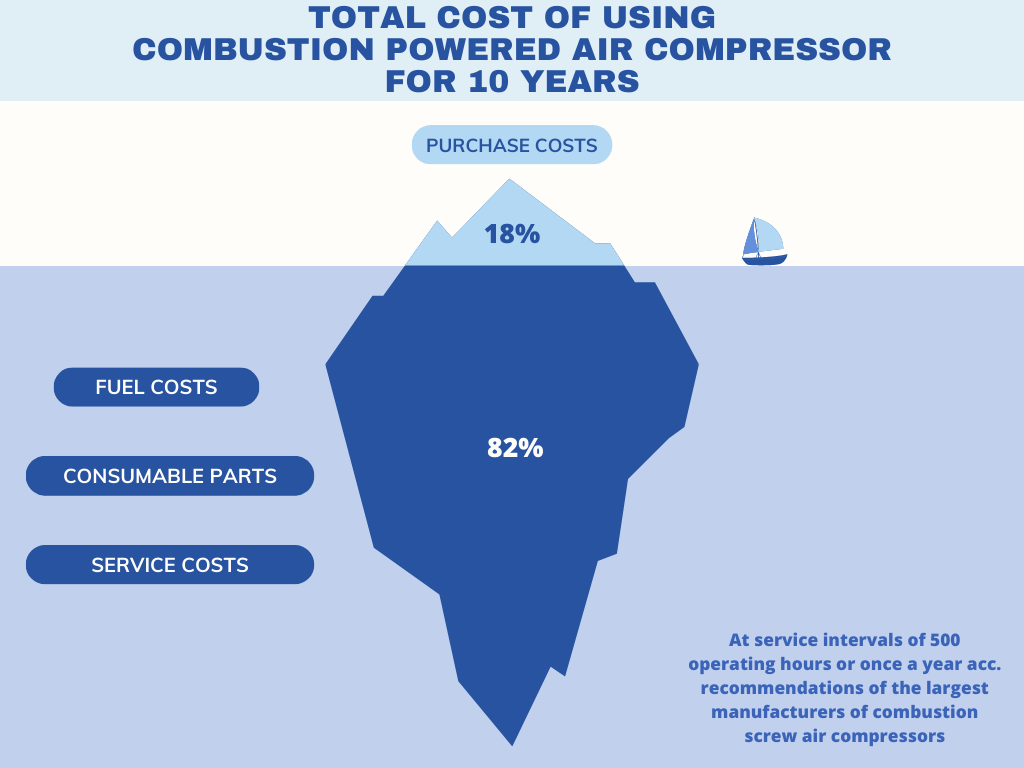

Diesel compressors are popular devices used in various industries, they can shorten the working time, in some industries many times, but this does not mean that it does not involve costs.

Before purchasing a diesel compressor, it is important to understand the operating costs that can affect your budget and profitability.

Fuel

One of the main operating costs of a combustion compressor is fuel. Rotair air compressors are powered by petrol (VRK and MDVN 32B series) and diesel oil (all MDVN and MDVS series). The cost of fuel will depend on current prices and the power of the engine that drives the screw compressor.

❗With proper operation and maintenance, the operating costs of the most popular models of diesel compressors (3-5 m3) over 10-12 years of use may exceed 149 000 EUR!

Reduction of operating costs

By focusing its attention on continuous improvement of its solutions, Rotair has introduced many solutions that make Rotair compressors the best choice for small and medium businesses in need of a trusted partner and a solution that will not let you down.

Rotair’s completely designed screw compressor architecture can reduce fuel costs by more than 20%.

Solutions such as:

✅Extremely effective pneumatic control system developed by ROTAIR for automatic engine speed control.

✅Asymmetric profile with oil injection in the compressor.

✅Rotair patented device that reduces fuel consumption by up to 20% – optional, highly cost-effective device on MDVN and MDVS series diesel air compressors;

All of the above solutions ensure lower fuel consumption, and thus, the costs incurred by the company for the needs of powering the air compressor performing the work.

Consumable parts and service

Thanks to the well-thought-out design of Rotair compressors, servicing is simple and quick. Thanks to the use of screw-on filters and their appropriate arrangement under the housing, the entire service can be performed in less than 60 minutes.

✅Service during the warranty: In the event of the need for technical inspection, repair or service of Rotair compressors, it is recommended to use an authorized service. Authorized service performs work using only original spare parts.

✅Rotair covers all repair costs related to manufacturing defects or replacement of parts that do not comply with the order. After the end of the warranty period, the service can be performed on your own or in professional services or workshops.

Competitive differences

When you buy Rotair solutions, you automatically choose competitive costs related to original spare parts and oils for the compressor and internal combustion engine.

❗For example, the prices of oils for competitive compressors can cost the equivalent of all filters and separators, translating this into the most popular compressor models (3-5 m3) – a full service often exceeds PLN 2,700 each year (!), due to the margins imposed on spare parts, of which half may be due to the screw compressor oil alone.

✅As an example of a screw compressor oil, Rotair has a list of proven oils such as: Mobil Rarus 46 or Shell Corena 46, which are available immediately in the amount of approx. 90 EUR for 20 liters.

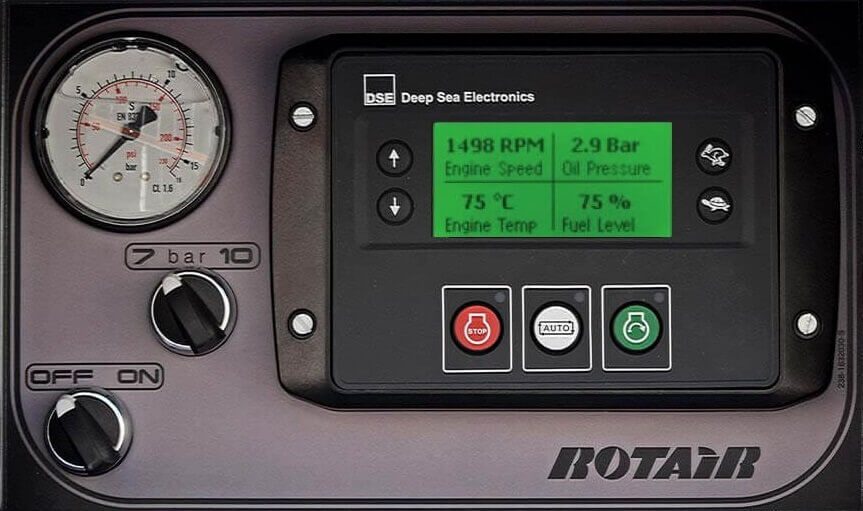

Technological solutions

Rotair has been improving its screw compressors for over 60 years, giving 100% of its attention only to this segment of machines. Innovations and improvements of the combustion compressor are constantly being introduced, based on the suggestions of our customers, thanks to which they improve the quality of work, transferring responsibility to the machine, eliminating operator errors

Examples of the latest solutions are:

- Variable working pressure, allowing any change of working pressure:

7->10 bars; 10->12 bar; 12-14 bar with variable displacement screw compressor. - “INTELLIGENT SYSTEM” Start/Stop, supplied by ROTAIR – prevents the risk of incorrect procedures during the start-up of the screw compressor.

- Extremely effective pneumatic control system for automatic engine speed control, which is included in every version of Rotair compressors.

Optional equipment of Rotair air compressors:

- Compressed air heater for MDVN 46/53/83 and MDVS 125

- Compressor option for extremely low temperatures

- Compressed air cooler with cyclone separator for MDVN and MDVS series

- Compressor and engine air filter clogging control system

- Higher pressure than in the catalogs up to 14/15 bar

- Double compressor air filter

- Two-stage engine air filter

- Drawbar with ball joint

- Dual Pressure System – Single capacity with single air valve set to highest working pressure

- Dual Pressure – Dual Capacity System for MDVN 46/53/83 and MDVS 125 (switch on control board)

- “BS” external aftercooler for the entire MDVN series

- Fuel level control with warning light

- Fuel saving device – ROTAIR exclusive patent (fuel saving up to 20%)

- Inline lubricator for MDVN and MDVS

- Spark arrestor for the MDVN and MDVS series

- Painting to order – painting of the chassis and body

- 130% double skin, sealed chassis

- Circuit emergency stop.

- Eberspeaker

- Chalwyn valve

- Stationary adapter – with the ability to quickly change the compressor from mobile to stationary and vice versa

ROTAIR has a special foot adapter to prepare the machine for standard foot delivery, which can be supplied as a separate attachment and be used to convert the mobile compressor to a foot compressor. And vice versa: after removing the adapter and mounting the chassis with all its parts, the original machine with legs can be towed with the running gear.

Click on one of the icons below to find out more about drawbar or portable chassis.

Our support and service

Our support and service

The Rotair company cares about its customers, offering professional support and comprehensive service. They have an extensive network of distributors and service centers who are ready to help if needed. This ensures that you can rely on support and quick access to the site in case of any problems or maintenance.

Regular technical inspections

Maintenance is essential to maintain high efficiency and reliability of the combustion powered screw air compressor.

Changing oils, air filters, oil separators, cleaning components – all this affects the efficiency and service life of the screw compressor.

It is also important to monitor the condition of the engine. It is the engine that is the heart of the entire compressor, it drives it and its condition translates into the efficiency of the screw compressor. Replacing the air filters, oil filter and engine oil itself can extend the life of the entire unit to the maximum of its capabilities, because it is the engine in Rotair compressors that is the first thing that will require a “big” service.

Versatility of use

Rotair air compressors are versatile and widely used in various industries. They can be used for a variety of works, such as: sandblasting, dry ice blasting, blowing, PUR foam and concrete spraying or to power drilling rigs and other pneumatic machines in trenchless technology.

Thanks to the variable working pressure regulation, Rotair compressors are extremely flexible and can work in different ranges, which allows you to adapt to different tasks and needs.

Regardless of the specifics of your project, Rotair will provide your company with the necessary tool to get the job done – efficiently and precisely.

Rotair – solution you can trust!

How to choose the right air compressor? Which diesel compressor will be the best?

Find out more about it in the lists below!