Cable stockings – Which one to choose?

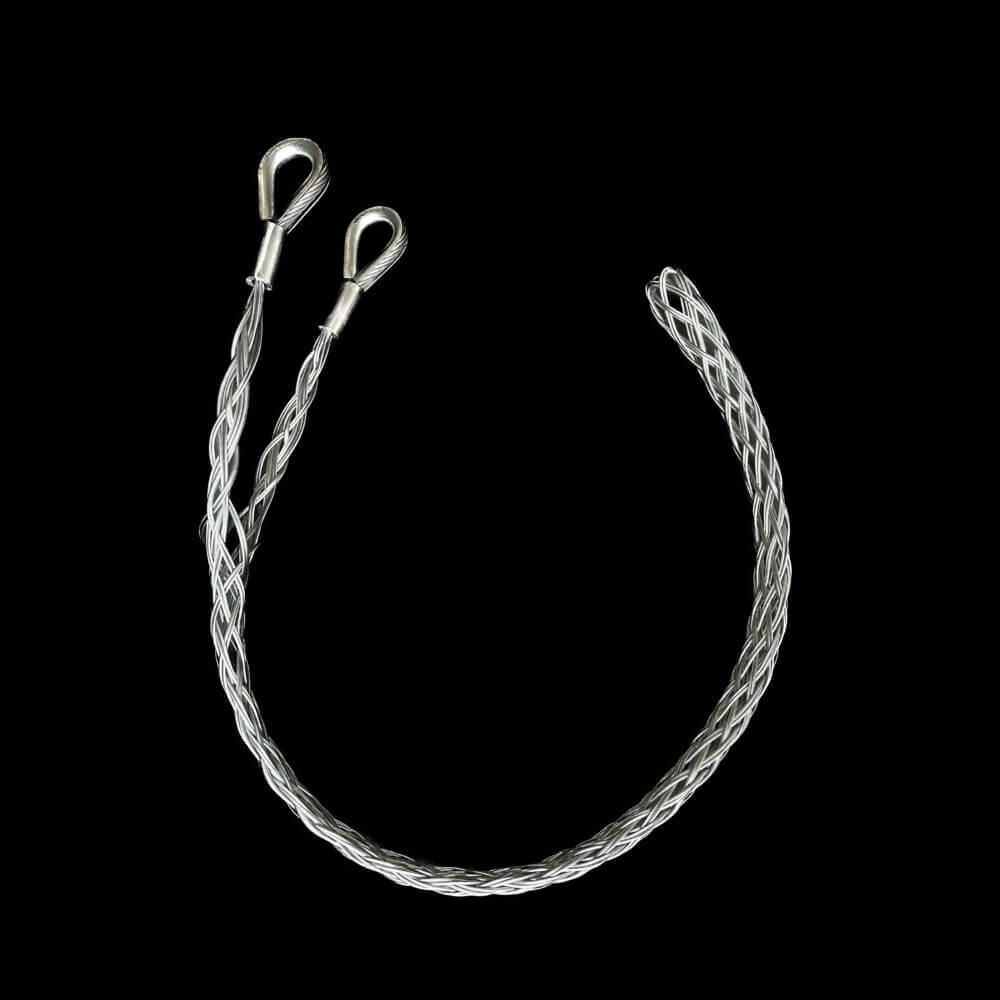

Cable stockings, also known as cable shrouds, are a product used to temporarily connect the cable to the rope when pulling the cable in cable culverts or trenches. They can be connected by means of a connector, e.g. model GF.10 or strain relief, e.g. model F250.R.12

They are also used to secure and protect cables against mechanical damage, including tensile, bending and breaking forces. The principle of assembly is very simple and consists in inserting the cable into the previously loosened mesh as shown in the picture. The mesh is made in such a way that it tightens on the cable when it starts to pull on the sheet’s eye.

Types of cable stockings

Today, there are many types and models of cable stockings used in various applications. They differ in the quality of materials and the method of execution adapted to the work performed and the required method of putting on, in particular:

Straight stockings, open stockings, two-ear stockings, connection stockings and three-wire stockings which we do not recommend due to their disadvantages in use.

One-eyed cable stocking

The most popular stocking, used to pull most power cables, mainly in excavation techniques.

Reinforced cable stocking

They are used for pulling cable and fiber optic lines. The characteristic “handle” at the beginning of the sheath protects fiber optic cables against too much pressure, comparing to classic cable stockings.

Two-eyed cable stocking

Used for cable and fiber optic lines.

Opened cable stocking

Cable stocking that can be worn anywhere on the cable while pulling. It is effective when the cable line requires further pulling, when the cable winch has already used the available rope to pull the cables.

What to look for when choosing cable stockings?

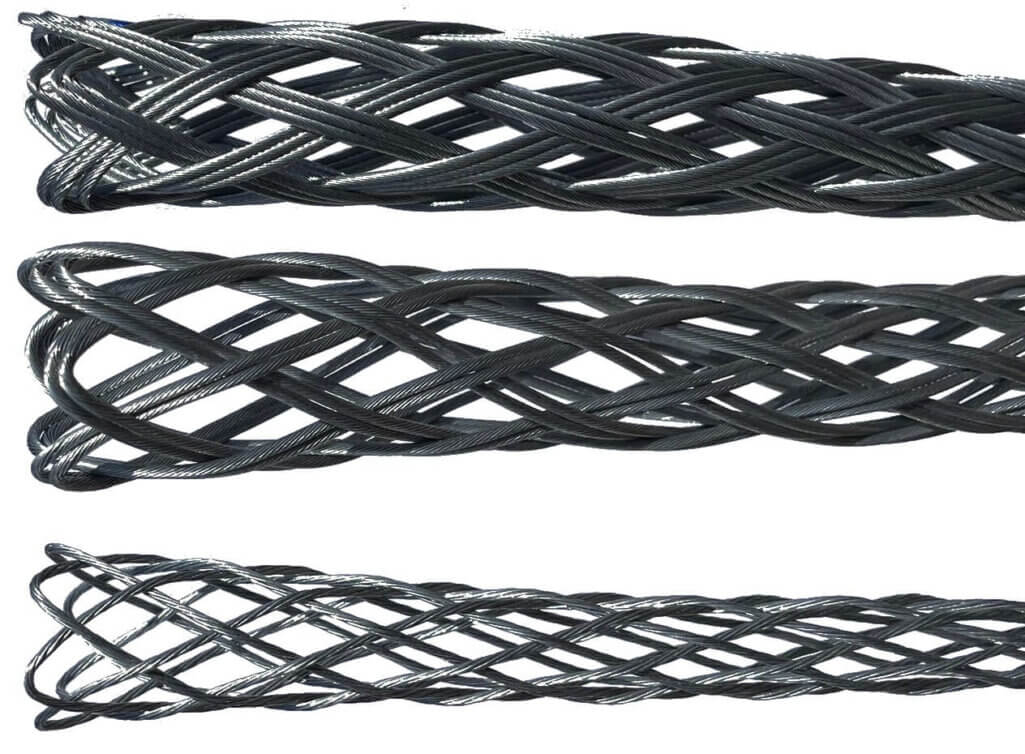

1. The breaking strength: of the cable stocking depends on the quality of the material used and the number and quality of the wires of the net braiding the cable, the workmanship itself and the pressing of the pulling eye.

Stockings made of single mesh lines tend to be less expensive and tend to have a lower breaking strength than stockings with double or triple mesh links. It is worth paying attention to the construction of the entwining mesh in order to choose stockings with adequate breaking strength.

2. Flexibility: The flexibility of the cable stocking is an important parameter that affects the ease of installation and resistance to deformation and proper clamping on the cable. Stockings with good flexibility are easier to adapt to different cable sizes and align properly without damage during installation.

High flexibility allows for easier assembly of the stocking and allows it to be adapted to different cable sizes. The cable stocking made of good quality steel does not deform and returns to its original shape after putting on and does not undergo excessive elongation and deformation.

3. Durability: The durability of cable stockings is closely related to the quality of the materials used. Cable sheaths are most often made of high-quality steel and galvanized, which make them more resistant to stretching and abrasion in difficult conditions.

- Steel cables are known for their high breaking strength. Thanks to this, cable stockings made of such lines are able to effectively protect cables against mechanical damage and mesh breakage

- Corrosion resistance: Appropriate galvanization of steel cords ensures their high resistance to corrosion. The zinc coating protects the wire against moisture and other weather conditions, which is especially important for outdoor applications, where the stockings are exposed to changing weather conditions and contact with various materials.

The appropriate braid and the number of braiding mesh lines affect the flexibility of the cable stocking and the secure grip of the cable, so it is worth considering the purchase of reinforced covers with more ropes and braid layers. First of all, because these sheaths are longer, so they distribute the force more evenly over the length of the cable, protecting it from damage.

Technical specification and safety factor of cable stockings

Breaking strength is one of the most important parameters of cable stockings, because without adequate resistance to tensile forces, there is a possibility of the stocking breaking, which can cause great problems when pulling the cable, and as a result, interruption of work, dismantling the cable and starting the pulling process again.

Breaking a cable stocking can generate very high costs related to additional work, and in extreme situations, damage to the cable and damage to the health of employees.

There are also fatal accidents after breaking a stocking or a rope, where, depending on the type of work, forces from 500 kg to even 10 tons occur when pulling the cable.

How to calculate the appropriate breaking force?

Breaking strength is measured in kN (kilonewtons) or kg (kilograms) and determines how much force a stocking can withstand before it breaks – called the breaking load (Breaking Load or BL) and is the basis for determining the maximum working load (Working Load or WL) ).

To determine the appropriate WL parameter, it is necessary to know the type of work carried out and the use of the appropriate safety factor (Safety Factor or SF).

Example: for work on cable lines, we use the safety factor SF = 3

This means that BL/3 = WL, i.e. the force with which the work WL can be performed with a cable stocking with BL 45kN is equal to 15 kN.

It is worth remembering to avoid damage during operation!

Check out our sale of cable stockings!

Did you liked our post?

Give us a review on Google!

The article is a work within the meaning of the Act of February 4, 1994 on copyright and related rights. All copyrights are vested in powerenergy.com.pl; Further dissemination of the work is possible only with the editor’s consent.