Air compressor for sandblasting – which sandblasting compressor to choose?

The heart of the sandblaster and the most important element is the combustion compressor. It is he who decides whether the entire sandblasting process will be a success, without any corrections.

Sandblasting is the cleaning of steel, wooden and other elements with a stream of sand, as well as engraving with sand under pressure on glass and the soda blasting method, i.e. cleaning under pressure, in which baking soda (Sodium Bicarbonate) NaHCO3 is just a few applications of the blast cleaning technology.

For cleaning dirt (sandblasting, soda blasting, shot blasting), abrasive is used, which is thrown with compressed air to clean elements from various dirt, removing e.g. rust, tarnish, grease and others that traditional methods of air cleaning, such as water or chemicals.

Air compressor with or without a water separator?

The outgoing compressed air is heated by the pressure and on discharge this air is condensed by the change in pressure.

In some devices, elevated temperature with steam particles is not recommended, for this purpose the compressor must be equipped with an aftercooler with a dryer.

How to measure sandblasting pressure?

Sandblasting usually uses special equipment called a blast chiller or compressor, which is equipped with a suitable compressor. The pressure that is needed for sandblasting depends on the type of surface, the type of sand and the sandblasting device.

For a blast compressor, a pressure between 4.5 and 6.2 bar (65-90 PSI) is usually used, but in some cases a higher pressure may be needed. Sand blasting units usually have a built-in compressor and allow for pressure regulation ranging from 4.5 to 8.3 bar (65-120 PSI).

The sandblasting compressor should be properly selected for the type of sand and the sandblasting device. For best results and safe use, it is recommended that you consult your equipment manufacturer and the sand you will be using for proper pressure recommendations.

Remember that high pressure can be dangerous if not properly controlled, so it is important to follow all safety guidelines when blasting.

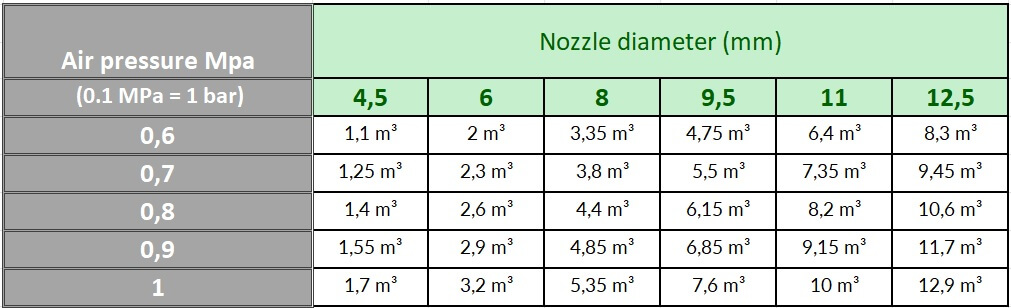

Table with matching petrol and electric air compressors according to the nozzle diameter of the sandblasters

In addition to the air compressor, you also need to know what sandblaster will be used. Below you can find suitable compressors for popular nozzles.

| Sandblasters 6-7bar | nozzle diameter [mm] | Air compressor models |

| mini sandblasters | 3 – 4 5 | VRK 16 or EG11 7 bar VRK 20 or EG11 7 bar |

| workshop sandblasters | 6 7 | MDVN 26 Eco 5 or EG15 7 bar MDVN 32B or EG18 7 bar |

| industrial sandblasters | 8 – 9 9 – 10 10 – 11 above 11 | MDVN 46 Eco 5 or EG26 7 bar MDVN 53 Eco 5 or EG26 7 bar MDVN 83 Eco 5 or EG45 7 bar MDVS 125 Eco 5 or EG55 7 bar |

Why Rotair screw compressors?

Rotair mobile air compressors are one of the most popular blasting compressors due to their reliability, durability and efficiency. Rotair offers various models of compressors, including diesel and screw compressors for sandblasting, which provide different levels of power and pressure. Thanks to this, the compressor can be adapted to the individual needs of sandblasting.

If you are interested in a proven and cost-effective sandblasting solution,

our compressors meet these requirements.

Air compressors for sandblasting

Do you like our post?

Leave us a review in Google!

The article is a work within the meaning of the Act of February 4, 1994 on copyright and related rights. All copyrights are vested in powerenergy.com.pl; Further dissemination of the work is possible only with the editor’s consent.