In today’s world where technology and connectivity play a key role, there is a constant need to install cables of various types and sizes.

This process can be time-consuming and demanding, but innovative lubricants such as the Italian Carima GLISS, the American Polywater Prelube or the German Katimex GLIT are becoming key accessories facilitating the installation of power, telecommunications and fiber optic cables.

Advantages of using lubricants for cables and fiber optics

The use of lubricant can be valuable in many situations, especially in the telecommunications and energy industries where cable installation plays a critical role. Here are some reasons why you should consider using a lubricant:

✅ Facilitating the installation process: The lubricant reduces friction between the cable and the wire, which makes it easier to pull cables into pipes, optical fibers into microducts or channels. This can speed up the installation process and reduce the risk of cable damage while pulling.

✅Improved efficiency: By reducing resistance, the lubricant allows cables to be pulled in longer distances, which in turn increases installation efficiency.

✅Cable Protection: Lubricant can protect cables from damage during the installation process. Acts as a protective layer, preventing scratches and other damage.

✅Cost Reduction: Simplifying the installation process and protecting cables can help reduce the costs associated with repairing and replacing damaged cables.

✅Use in difficult conditions: The lubricant may be particularly useful for installations in difficult conditions, such as installations in hard-to-reach places or when conditions in pipes/inlets are unsuitable

✅Long-term durability: Some lubricants retain their lubricating properties for a long time, which means that one application can provide benefits for many years.

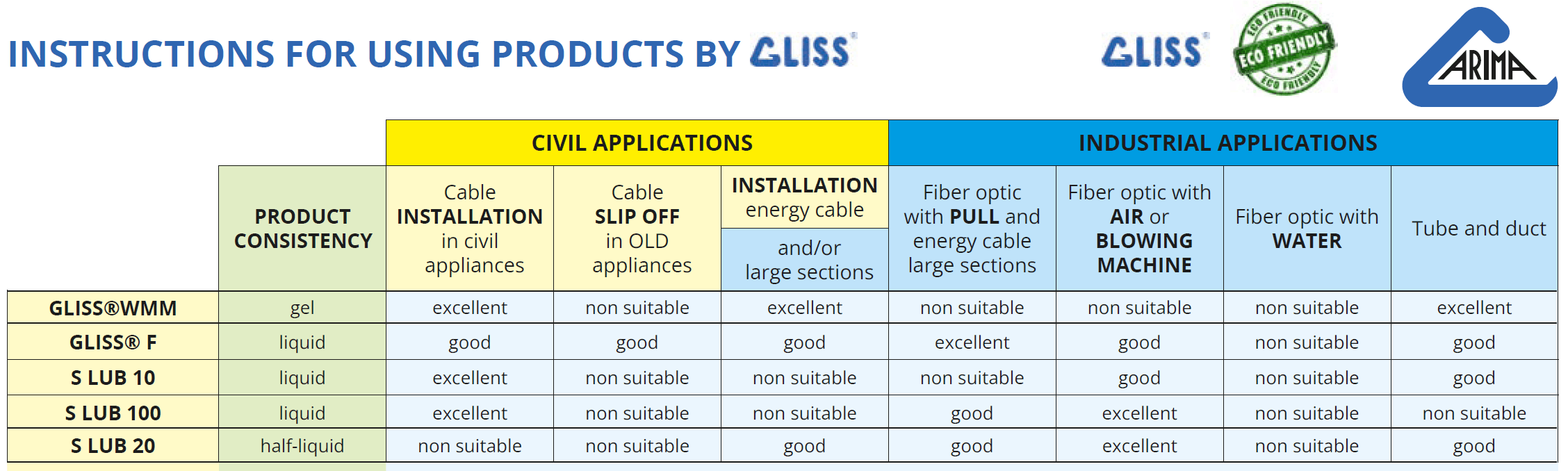

A table that matches the lubricant or gel to a specific task

Below we will look at these three products, their uses and the benefits they bring.

S LUB: Lubricant for blowing fiber optics

S LUB is a liquid lubricant gel that was created specifically for blowing optical fibers into microtubes and tube packages.

This is a product that can significantly facilitate the installation of microcables. The main features of the product are:

- Reduction of friction when blowing fiber optics, which significantly facilitates the process.

- Increasing the blowing range.

- Fully biodegradable and non-toxic.

- Compatible with all optical fibers.

Case study: Companies providing services of blowing fiber optics into microtubes believe that you should not start working with blowing machines without lubricant.

S LUB 10

The water-based composition S LUB 10 is primarily a very effective lubricant, ensuring a drastic reduction in friction.

Recommended for installing fiber optic cables in channels with an internal diameter of 4 to 20 mm.

S LUB 100

The S LUB 100 is an improved, more cost-effective version of the S LUB 10, a tool for companies blowing fiber optics into 4 to 20 mm diameter tubes, helping them achieve even better blowing results with less time and, therefore, costs.

S LUB 20

S LUB 20 adheres perfectly to the cable surface or the inner surface of the pipe. It leaves a very thin layer of lubricant and does not create a sticky effect. Recommended for installing fiber optic cables in channels with an internal diameter of 20 to 50 mm.

GLISS® F: The universal solution for installing small diameter cables

GLISS® F is a very efficient lubricant intended for pulling small diameter power cables, fiber optic cables and even microducts. This is a product that not only facilitates the installation process, but also contributes to increased efficiency and savings. The main features of the product are:

- Reducing the resistance when pulling in cables by up to 90%, which translates into a longer installation distance.

- Durability and protection of cables against dirt, even many years after use.

- Can be used in the presence of water.

- Perfect adhesion to the cable surface.

Moreover, GLISS® F is used not only in fiber optic cable installations, but also in telecommunications, coaxial and power cables. It is a universal solution for companies with a wide scope of work.

GLISS® WMM: Sliding gel for pulling power cables and pipes

GLISS® WMM is a lubricant gel that has been designed for manual lubrication of power and telecommunications cables that are pulled in using cable winches. This is an integral part of the cable installation process and brings numerous benefits:

- 80% reduction in resistance when pulling in cables, making work easier and more efficient.

- Creating a durable and non-invasive lubricant layer on the cable after the water evaporates, which facilitates subsequent cable pulling.

- Compatible with various types of cables except resin coated ones.

It is worth noting that GLISS® WMM is an integral element in the cable pulling process and can significantly speed up and facilitate this operation.

Case study: PeBeKa (and subcontractor WUPRINŻ) providing services for the KGHM mine, after using lubricant gel, reduced the rope tension when pulling in a new pipe in an old pipeline from 180 kN to an average of 40 kN.

However, it is worth remembering that the choice of the appropriate lubricant should be carefully considered, taking into account the type of cables, installation environment and product specifications.

Carima GLISS® F

Do you like our post?

Leave us a review on Google!

The article constitutes a work within the meaning of the Act of February 4, 1994 on copyright and related rights. All copyrights belong to powerenergy.com.pl; Further distribution of the work is possible only with the consent of the editors.