Compressed air quality – ISO 8573-1:2010 standard

Using the ISO 8573-1:2010 standard to ensure high quality compressed air is extremely important.

High quality compressed air plays a key role in various sectors, such as factories, transport, food and pharmaceutical industries.

Depending on the specific application, the compressed air quality required may vary. In some industries, such as food and pharmaceutical manufacturing, air purity is paramount, while in others, reliability and durability of pneumatic tools are key considerations.

Screw compressor air filter

Filtering the compressed air is usually necessary because the air leaving the compressor can contain various contaminants such as dust, salt, sugar, soot, rust, cement particles, paint, and even bacteria and viruses.

Contaminants are harmful to pneumatic tools and devices as well as to production processes and final products. Therefore, filters are essential to ensure high quality and reliable production. However, it is important to determine your own air quality needs as this affects the selection of the right filters.

The ISO 8573-1:2010 standard provides helpful guidelines in determining the required level of compressed air purity. Thanks to this standard, it is possible to determine the permissible content of various contaminants in compressed air, such as moisture, particles and oil. This standard classifies contaminants into three main categories and defines several purity classes for each of these categories.

Purity of compressed air for blasting and dry ice blasting.

Defining the right level of compressed air purity is important for two reasons. First, some applications require specific air quality standards, and non-compliance can result in financial sanctions or production shutdown.

Secondly, a higher level of air purity can lead to higher production costs, including with additional devices and components, such as compressed air dryers and coolers, as well as higher energy consumption. Therefore, it is important to find the right balance between air quality and costs, which brings both financial and environmental benefits.

Water contained in compressed air can damage the nozzle and seals of the dry ice blasting equipment, therefore, to ensure maximum safety and quality of service, it is crucial to understand the requirements set out by the ISO standard and adapt the filters to these requirements.

What are the standards?

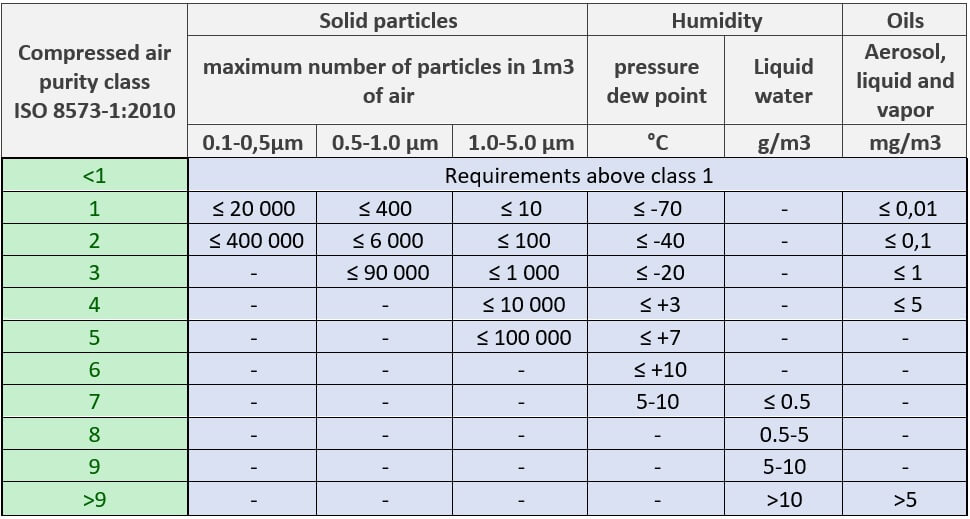

Depending on the air purity class, the required quality varies. Lower class air must be cleaner than higher class air. For example, Class 4 air may contain more pollutants than Class 3 air.

The ISO 8573-1:2010 standard defines the limit of solid particles per cubic meter of air, taking into account different particle size ranges. For example, Class 1 air may contain up to 20,000 particles between 0.1-0.5 microns, up to 400 particles between 0.5-1 microns, and up to 10 particles between 1-5 microns.

For Class 2 air, higher particle counts are acceptable, for example, a maximum of 400,000 particles between 0.1-0.5 microns, a maximum of 6,000 particles between 0.5-1 microns, and a maximum of 100 particles between 1-5 microns .

For class 3, the content of particles in the first category is not specified, and from class 6, the ISO standard only focuses on the mass concentration of particulate matter in milligrams per cubic meter.

For moisture, purity grades are defined by the pressure dew point for the more stringent grades (lower grades) and the liquid content of the air in grams per cubic meter for air grades 7 through 9. For example, Class 1 air must have a dew point not lower than -70°C, while Class 9 air may contain 5-10 g/m3 of water and/or water vapor.

In the case of oil, the purity class is determined by the oil content in mg/m3. Class 1 air may contain a maximum of 0.01 mg of any type of oil, while Class 4 air has an oil content limit of 500 times that (5 mg/m3).

The choice of the appropriate filter depends on the specific class of air purity according to the ISO standard. For example, the filters on all Rotair compressors are designed to meet Class 1 for particulate matter and Class 1 or 2 for oil depending on the model.

Compressed air purity classes table for ISO 8573-1:2010

Which compressor to choose for sandblasting and dry ice blasting?

Conclusion: The use of ISO 8573-1:2010 to ensure the quality of compressed air is extremely important for various industry sectors. Air filtration is essential to remove harmful contaminants. Determining the required level of air purity in accordance with the ISO standard and the selection of appropriate filters are crucial to ensure high quality production.

It is worth checking the offer of Rotair combustion compressors, because all devices are adapted to stringent guidelines and are highly valued in the sandblasting and dry ice blasting industry thanks to their reliable air and oil filtration.

Each Rotair mobile compressor can be adapted for professional sandblasting and dry ice blasting thanks to the integrated cooler with a water separator. The temperature coming out of the compressor can be reduced to an ambient temperature of +0°C down to +13°C depending on the model of the Rotair mobile compressor.

Check our diesel air compressor offer!

The article is a work within the meaning of the Act of February 4, 1994 on copyright and related rights. All copyrights are vested in powerenergy.com.pl; Further dissemination of the work is possible only with the editor’s consent.

Do you like our post?

Give us a review on Google!