Which air compressor for dry ice blasting?

One of the key elements of this process is a suitable source of compressed air that provides the energy needed to generate the dry ice stream. In the case of work carried out in the field, where access to a local source of compressed air may be limited or impossible, the use of mobile diesel air compressors, such as those offered by Rotair, is an ideal solution.

What should you pay attention to when choosing a diesel compressor?

- Adequate air pressure and flow: The compressor should provide sufficient air pressure, which is necessary for effective dry ice blasting. Adequate air flow is also important to ensure the smooth operation of the cleaned surfaces.

- Clean and dry compressed air: The compressor should deliver compressed air free of oil, moisture and contamination. Air filters and an oil and condensate separation system are essential in keeping the air clean.

- Compressed air temperature: The compressor should deliver compressed air suitable for ambient temperatures.

Depending on the operating temperature of the screw compressor, the compressor should be equipped with a compressed air cooler and/or heater if the ambient temperature drops below 0°C. - Mobility: The compressor should be portable and easy to transport. This allows you to perform cleaning work in various places, both inside and outside the facilities.

- Safety: The compressor should be equipped with appropriate protections and safety functions, such as excess heat removal systems, overload protection or emergency stop functions, which is especially important in closed rooms.

Meeting these requirements is essential for effective and safe dry ice blasting. When choosing a compressor for this cleaning method, it is worth paying attention to these factors and finding the device that best suits your individual needs and working conditions.

Air compressor air pressure and efficiency

It is important to select a screw air compressor with the correct pressure and airflow for the specific application, taking into account the requirements of dry ice blasting. It is always recommended to consult the manufacturer or a dry ice blasting specialist to select the right compressor for your specific needs.

Air compressor air pressure

The compressor should reach a pressure high enough for the compressed air to effectively remove dirt using a jet of dry ice. For dry ice blasting, the pressure is typically between 5 and 16 bar (70-230 psi), depending on the application and the type of soiling.

Air compressor airflow

The amount of compressed air generated per unit of time is also important. In the case of dry ice blasting, the compressor capacity should be high enough to supply enough compressed air to power the cleaning device.

Air compressor airflow is measured in liters per minute (l/min) or cubic meters per minute (m³/min). The specific performance depends on many factors, such as the size and complexity of the application, the amount and type of soiling, and the efficiency of the cleaning device.

For dry ice blasting, the compressed air required varies from 1 m3 to 5 m3 depending on the cleaning machine used.

Compressed air quality

Dry ice blasting requires compressed air quality according to ISO 8573-1:2010 standard, which affects the effectiveness and efficiency of this process. There are several factors to consider to ensure the compressed air quality needed for dry ice blasting.

Filters and oil separator in a screw compressor

The first factor is the purity of the compressed air. Screw compressors suck in the surrounding air, and the quality of the compressed air depends on the quality of the filters used. Therefore, it is important that the compressor is equipped with appropriate filters that effectively remove contaminants such as oil residues. In the case of Rotair diesel compressors, the permissible oil content in the compressed air is usually 1-2 PPM.

More about the quality of compressed air for dry ice blasting can be found on our blog.

Water in compressed air

Another factor is the humidity of the compressed air. Screw air compressors suck in air with a certain amount of moisture, and in the compression process the air is saturated with moisture. Moisture can compromise cleaning performance in some applications.

Compressed air cyclone separators

Therefore, it is essential that the compressor is equipped with suitable aftercoolers with a cyclone separator and an automatic condensate drain. These components effectively remove excess moisture from the compressed air, ensuring optimal conditions for dry ice blasting.

Compressed air temperature

The last factor is the temperature of the compressed air. The high temperature after compression contributes to a higher moisture content.

Aftercooler with cyclone separator, automatic condensate drain and air preheater are essential elements in the dry ice blasting process.

Compressed air aftercooler with water separator

An aftercooler cools the compressed air, a cyclone separator removes excess moisture, and an automatic condensate drain removes condensed moisture.

An aftercooler with a separator is even required when operating at temperatures between 20°C and 40°C. This is especially important if the compressor is placed indoors.

Compressed air heater

The air heater raises the temperature of the compressed air if the compressor is operating at temperatures below 0°C, preventing additional water condensation. This eliminates residual moisture in the compressed air, minimizing the risk of freezing of the dry ice blasting machine.

Why Choose Customized Rotair Dry Ice Blasting Compressors?

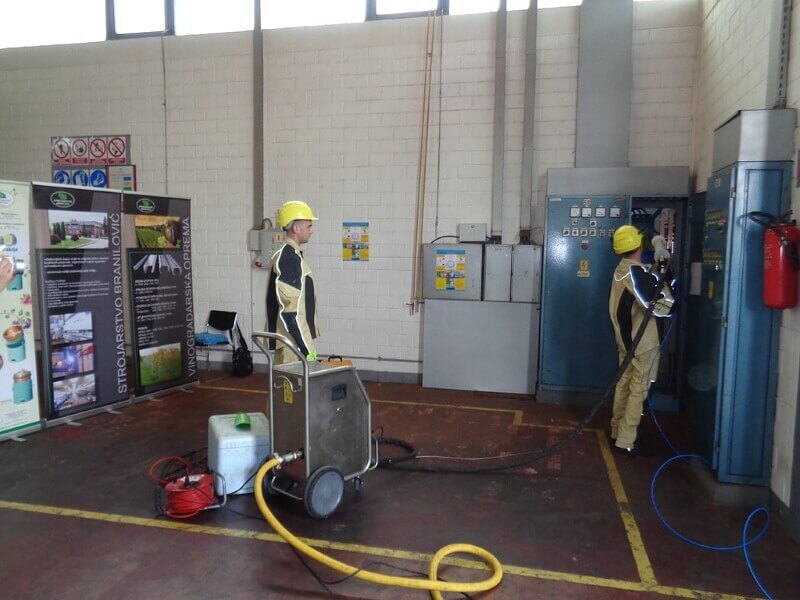

Dry ice blasting with Rotair diesel compressors is an effective and cost-effective method of powering your cleaning machine. Thanks to the high quality of compressed air, provided by the right compressor equipment, excellent cleaning results can be achieved.

Filters and separators effectively remove impurities and solid particles, ensuring class 1 compressed air quality at the level of 1-2 PPM.

Models of MDVN and MDVS series portable diesel compressors, offered by Rotair, are optionally equipped with air heaters and final coolers with a cyclone separator. They allow for trouble-free operation of the cleaning device with the possibility of automatic change of the working pressure of the compressor from 7 to even 13 bar, depending on the model and use.

Not only are Rotair diesel compressors reliable and efficient, they meet emission and noise standards, making them the ideal solution for dry ice blasting in a variety of environments.

If you are interested in a proven and cost-effective dry ice blasting solution,

our compressors meet these requirements.

Air compressors offer for dry ice blasting

Do you like our post?

Give us a review on Google!

The article is a work within the meaning of the Act of February 4, 1994 on copyright and related rights. All copyrights are vested in powerenergy.com.pl; Further dissemination of the work is possible only with the editor’s consent.