The proper swivel joint for the winch choice depends on several factors, such as wire rope size and specifications, cable winches, and application.

A swivel joint is a type of device used to rotate or lay a rope, or in some other application. This is useful when the rope needs proper guidance and avoids twisting when pulling or lifting heavy objects.

Cable winches, also known as hydrualic cable pullers, are devices used to pull, lift or move heavy objects, especially in construction, industry or forestry.

Cable winches have different capacities and power, and the choice of the right model depends on the weight and characteristics of the object to be moved or lifted.

Do I need to use a swivel when pulling a wire rope?

The use of a swivel in cable winches depends on several factors:

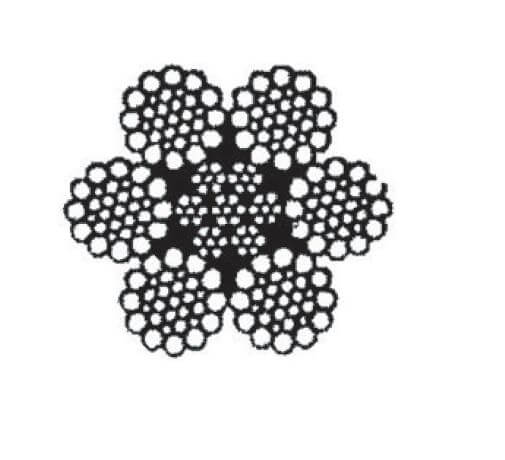

- Type of wire rope: Some wire ropes are manufactured in such a way as to reduce rotation, called non-swivel. Such lines not only do not need a swivel, but are weakened by it. Other ropes may twist more when pulled. The use of a swivel can reduce rope twist and make work easier.

- Application: In some applications where the rope must be properly guided to avoid twisting or tangling, a swivel can be very helpful, mainly to avoid rope twisting when lifting heavy objects or when working with ropes where rotation can be an issue.

- Winch size and type: Some cable winches, especially those with higher capacity, have built-in mechanisms to minimize rope twist. In this case, additional use of the swivel may not be necessary. Using a swivel to pull the wire rope with the winch can lead to dangerous situations and even damage the winch or the rope and cable.

- Manufacturer’s Guide: It’s always a good idea to read the manuals and recommendations from the manufacturer of both the winch and the wire rope itself to find out if they recommend or advise against using a swivel.

Conclusion: If you are dealing with a steel line that tends to twist when pulled, and the manufacturer of the winch and rope recommends the use of a swivel, then it is worth using this solution. Otherwise, if there is no need or the swivel is not recommended by the manufacturer, it may not be necessary to use it. Also remember that safe use of the winch and rope is essential, so always follow the manufacturer’s recommendations and proper safety procedures.

If you want to know in more detail whether to use a winch swivel, please refer to the article below.

This article, published in April 2020, analyzes the use of active linear anti-friction swivels with different types and grades of steel cords. The study highlights that the use of such swivels in most steel lines can have a negative impact on their service life and lead to unpredictable operating conditions.

Impact on the performance of wire ropes

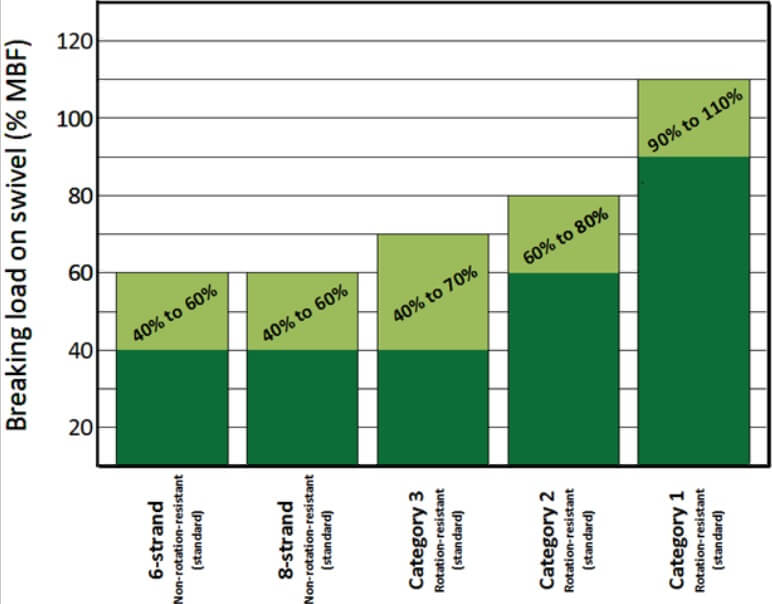

Breaking Strength Reduction: The use of an active, linear swivel in standard steel lines (insensitive to rotation) can significantly reduce their breaking strength.

Tests have shown that such wire ropes, when loaded and allowed to rotate with a swivel joint for the winch, fail between 40% and 60% of their minimum breaking strength (MBF = minimum breaking forces).

Negative impact on performance and lifespan: The use of an active, linear swivel can negatively affect the performance of steel lines and shorten their life. Operational loading and unloading of the wire rope shifts the load balance between the inner and outer strands, leading to accelerated internal wear and fatigue.

Deformation and Fatigue: Under load, the finely laid strands of standard steel cables tend to straighten out and release torque. This can lead to various deformations and damage to the wire rope, contributing to material fatigue.

Rotation resistant steel ropes

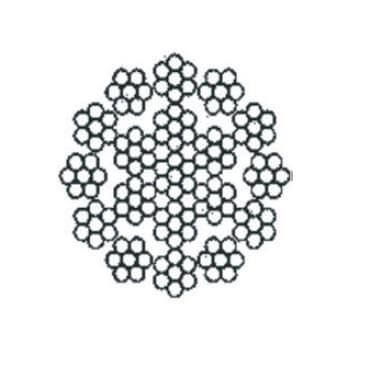

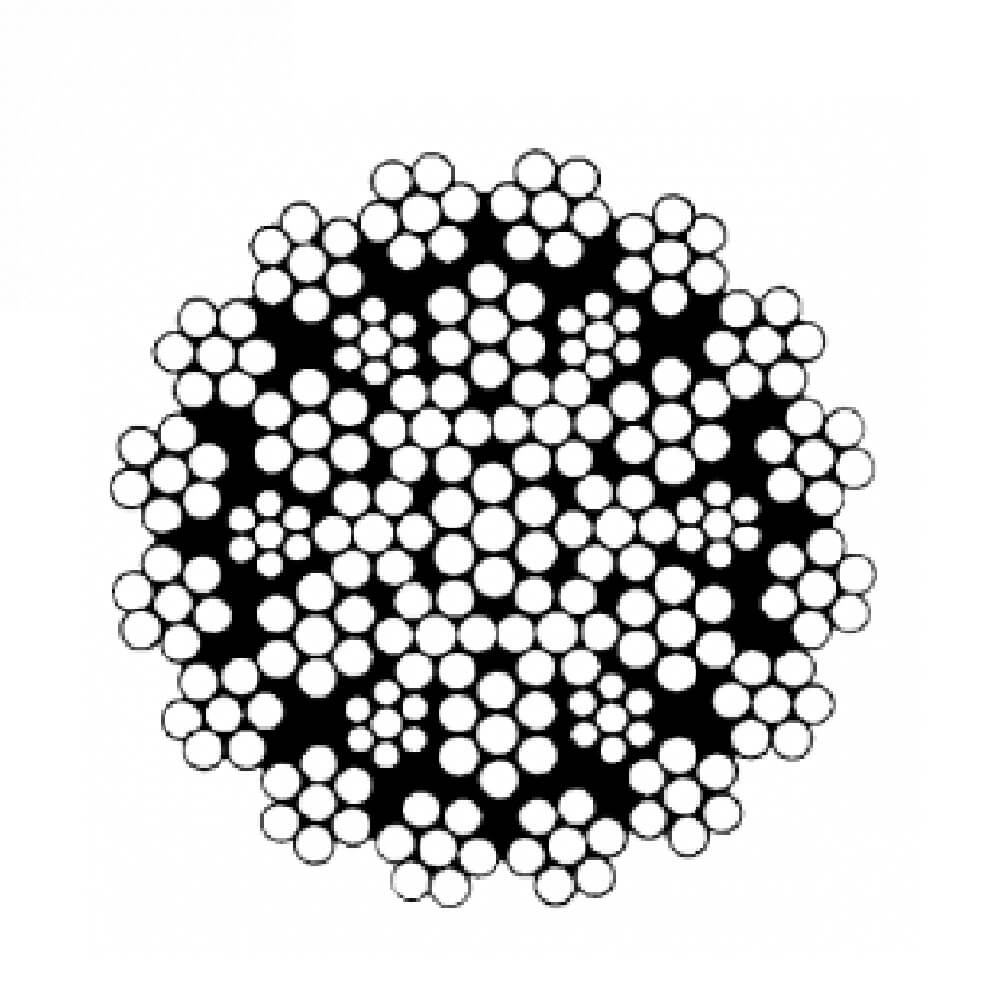

Rotation resistant wire ropes are designed to prevent the problems seen with standard wire ropes. The outer strands in rotation resistant steel lines are laid in the opposite direction to the inner strands, reducing the torque on the wire rope. ASTM A 1023 classifies rotation-resistant wire ropes into three categories based on their resistance to rotation:

Category 1.

No or little tendency to rotate

Category 2.

Significant resistance to rotation

Category 3.

Limited resistance to rotation

Category 1: No or slight tendency to rotation – Rope model C02..AC

Category 2: Significant resistance to rotation – Rope model C02..LR

Category 3: Limited Resistance to Rotation – Rope Model C02..AT

Recommendations

Use of Active Linear Anti-Twist Swivels: The article strongly advises against the use of Active Linear Swivels with any type and grade of wire rope that is not designed to exhibit the same rotational characteristics as Category 1 anti-rotation wire rope. Their use can lead to internal degradation, core overload and potential failure of the wire rope.

Proper use of the swivel: It is recommended to check the wire rope manufacturer’s certification for details on the allowable use of the swivel. If required, technical representatives can also be contacted for advice on the correct use of wire rope swivels.

Recommended Wire Rope: If an active linear anti-friction swivel is to be used, it is recommended to combine it with a Category 1 anti-rotation steel line. The use of a proper rotation resistant wire rope can even improve the performance of the wire rope in service.

The study highlights the importance of judicious use of active linear torsion stress relievers with wire ropes. He warns against their use in standard steel lines, which can lead to reduced breaking strength, negative impact on productivity and accelerated material fatigue. Instead, it recommends the use of appropriate anti-rotation steel wire ropes or the consultation of technical experts to ensure the safe and effective use of wire ropes.

Did you liked our post?

Give us a review on Google!

The article is a work within the meaning of the Act of February 4, 1994 on copyright and related rights. All copyrights are vested in powerenergy.com.pl; Further dissemination of the work is possible only with the editor’s consent.